3D Printing is sneaking up on us again!

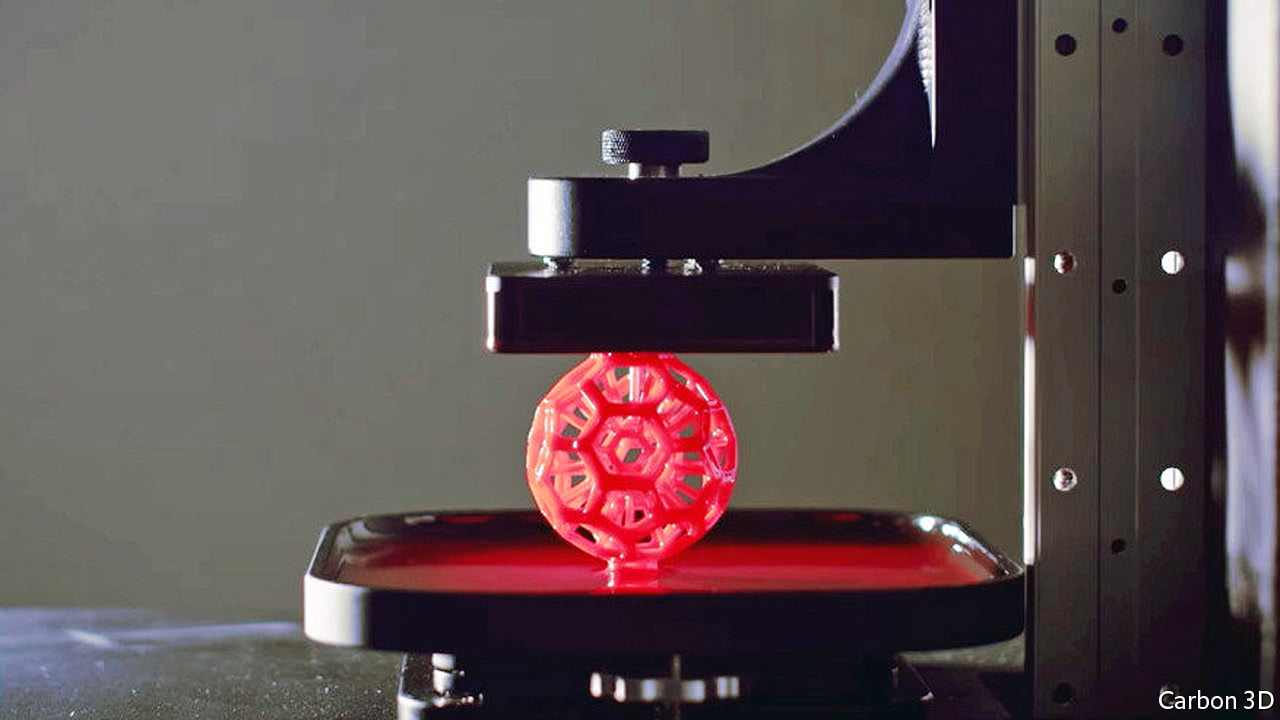

3D Printing originated in the 1980s, with pioneers like Chuck Hull, who patented the stereolithography fabrication system. Such a machine allows a product to be designed on a computer screen and then "printed" as a solid object by building up successive layers of material. Stereolithography is among dozens of approaches to 3D printing (also known as additive manufacturing). Printing has become a popular way of producing one-off prototypes, because changes are more easily and cheaply made by tweaking a 3D printer's software than by resetting lots of tools in a factory. That means the technology is ideal for low-volume production, such as turning out craft items like jewellery, or for customising products, such as prosthetics. Skeptics say that 3D printers are too slow and too expensive - it can take two days to create a complex object. However, some of the new methods of 3D printing now emerging show that its shortcomings can be overcome. Adidas, for one, has started to use a remarkable form of it called "digital light synthesis" to produce the soles of trainers, pulling them fully formed from a vat of liquid polymer. The technique will be used in a couple of new and highly automated factories in Germany and America to bring 1 million pairs of shoes annually to market much more quickly than by conventional processes. A new technique called bound-metal deposition has the potential to change the economics of metal printing, too, by building objects at a rate of 500 cubic inches an hour, compared with 1-2 cubic inches an hour using a typical laser-based metal printer. Are we entering the age of additive manufacturing? More here.

3D Printing originated in the 1980s, with pioneers like Chuck Hull, who patented the stereolithography fabrication system. Such a machine allows a product to be designed on a computer screen and then "printed" as a solid object by building up successive layers of material. Stereolithography is among dozens of approaches to 3D printing (also known as additive manufacturing). Printing has become a popular way of producing one-off prototypes, because changes are more easily and cheaply made by tweaking a 3D printer's software than by resetting lots of tools in a factory. That means the technology is ideal for low-volume production, such as turning out craft items like jewellery, or for customising products, such as prosthetics. Skeptics say that 3D printers are too slow and too expensive - it can take two days to create a complex object. However, some of the new methods of 3D printing now emerging show that its shortcomings can be overcome. Adidas, for one, has started to use a remarkable form of it called "digital light synthesis" to produce the soles of trainers, pulling them fully formed from a vat of liquid polymer. The technique will be used in a couple of new and highly automated factories in Germany and America to bring 1 million pairs of shoes annually to market much more quickly than by conventional processes. A new technique called bound-metal deposition has the potential to change the economics of metal printing, too, by building objects at a rate of 500 cubic inches an hour, compared with 1-2 cubic inches an hour using a typical laser-based metal printer. Are we entering the age of additive manufacturing? More here.